Prius Sets Efficiency Record

This probably more properly should say that a skilled hypermiler – Wayne Gerdes – set a hybrid vehicle efficiency record in a Prius. But as Toyota sponsored the record-setting drive, the automaker gets to put its brand first.

In any event, Gerdes drove a 2023 Prius LE in May from Los Angeles City Hall to New York City Hall, a distance of 3,211.7 miles (it wasn’t a straight line), achieving overall fuel efficiency of 93.158 miler per gallon.

That beat the previous, 8-year-old L.A.-N.Y. hybrid efficiency record (also held by Gerdes, in a 2017 Kia Niro hybrid) by almost 18 mpg and got Toyota, the Prius and Gerdes (again) into the Guinness Book of World Records.

Gerdes said he crossed a mountain pass at 7,000 feet, hit 105-degree temperatures in California’s Mojave Desert and fought strong winds blowing in off the Gulf of Mexico as he traversed the country.

The Prius wasn’t altered – as some cars are in fuel economy runs – so there were no special spoilers, covered wheel housings, missing sheet metal and the like.

A hypermiler does have to put up with long, slow days of carefully controlled driving, though. and, says Gerdes, must be ready to alter route plans if weather or other conditions cause problems.

Gerdes’ tips for achieving the best possible efficiency in everyday driving are pretty straightforward: No quick starts; even pressure on the accelerator (cruise control helps there); reasonable and steady speed and, whenever possible, coast up to stop signs, red lights and into parking lots, letting the car’s momentum diminish naturally unil applying the brakes – softly – at the last possible moment.

To that we’d add that you should keep your tires inflated to the maximum recommended pressure and, if you are really dedicated to efficiency, minimize heater and air conditioner use.

Solid-State EV Batteries Getting Closer (All dates subject to change!)

Solid-state batteries have been on the horizon for years now as a major breakthrough in improving EV range while reducing costs and battery fire danger. Production goals jeep getting pushed back, though, as development difficulties stymie battery makers. Recent news, however, seems more positive. What follows is a wrap up of significant items.

Toyota says it has received official Japanese government ok to start building a solid-state battery factory and that it plans to introduce solid state batteries in limited quantities for production models as early as 2027.

Solid state batteries don’t use a liquid electrolyte and greatly reduce the rise of lithium fires. they also can charge faster without battery-damaging heat buildup and are lighter and more energy dense that conventional lithium-ion batteries, giving automakers the option of using less battery – a huge cost savings – to achieve the same range or using the same-size battery but delivering more range than conventional EV batteries.

Mercedes-Benz is partnering with a Boston company, Factorial, to develop solid state batteries, and has just announced that it will start road-testing later this year and hopes to have electrified vehicles with solid-state batteries in dealerships by 2030. Mercedes also is working with a Taiwanese company, ProLogium. Having two or more battery partners helps ensure a steady flow of cells

Factorial also wants more than just one customer and in addition to Mercedes-Benz has solid-state battery development deals with Stellantis and the Hyundai Motor Group’s Hyundai and Kia brands.

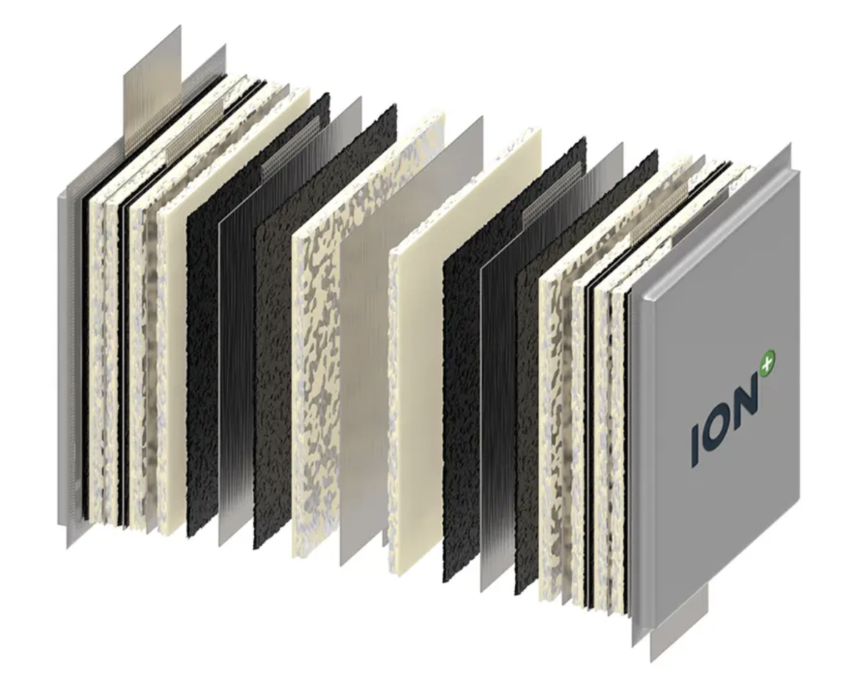

ION Storage Systems, a solid-state battery developer in Maryland, says it is moving closer to commercial production of its anode-free batteries, recently achieving 800 charge-discharge cycles it is solid state cells without requiring any compression.

That’s an important achievement because most solid-state cells swell during use, requiring specialized manufacturing techniques and expensive pressurized cases. ION’s cells retain a constant volume and can be packaged in traditional pouches – as used for most liquid-electrolyte lithium-ion batteries.

Nissan, which looked to have gone to sleep in the EV department after introducing the world’s first mass-production model (the Leaf) in 2010, has shown off a pilot production plant for solid-state batteries and says the Yokohama factory will be producing prototype batteries by early 2025 with a goal of commercially viable batteries – likely in small volume at first – by the spring of 2028.

China doesn’t make lots of news on the solid-state front because it likes to keep things close to the vest.But a Chinese company, WeLion New Energy Technology, has already started selling “semi solid-state” EV batteries that use a gel instead of a more flammable liquid for the electrolyte. The batteries reportedly save weight and mass and are more energy dense. WeLion says its cells can store almost a third more energy per kilogram than conventional lithium-ion EV batteries.

Chinese automaker Nio reportedly starting using the WeLion batteries late last year in one EV model offered for rent in China. Recently a second Chinese automaker, IM Motors, said it has started selling EVs with a similar semi solid-state battery chemistry. No word on whether it is from the same battery maker; information from IM is just that the batteries are supplied by its parent, China’s SAIC automotive group. SAIC in turn has said it intends to have fully solid-state batteries for IM vehicles in 2027.